I'm running a stock Ender 5 pro with the filament that came with it, and using Creality Slicer 4.8.2, but I'm only able to get reliable bed adhesion if I increase the bed temperature from 50 to 60 °C for the bottom layer and decrease the print head speed by about 75 % from the default profile for the Ender 5.

The machine is absolutely stock, and is fresh out of the box except for bed levelling.

I used the default bed leveling print and that came out well, so I'm reasonably certain that it's not a bed leveling issue. The problem seems to be with models that I've made myself in blender and exported as STL files.

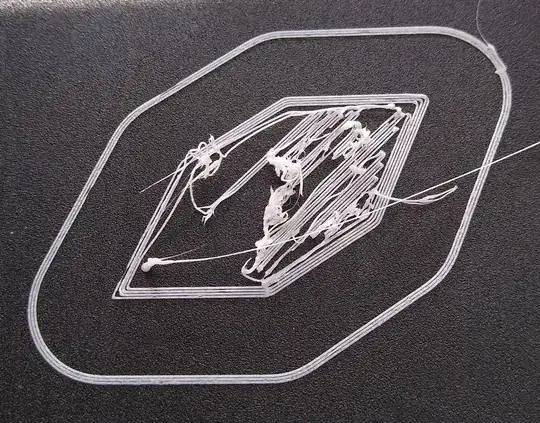

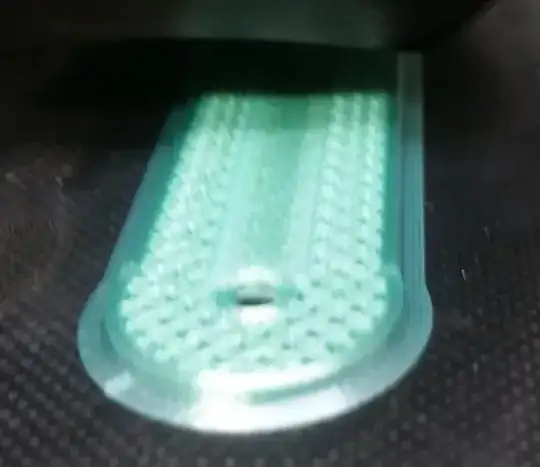

In all cases the raft that was generated by the Creality software has printed out perfectly, but the print has only partially gone down when it came to the model itself.