TL;DR;

If I calibrate my Y-axis steps/mm based on the long side of the model shown below, the calibration cube part is printed too big. If I calibrate the steps/mm based on the calibration cube part, the long side of the model comes out too short. Any ideas/hints on what the problem is?

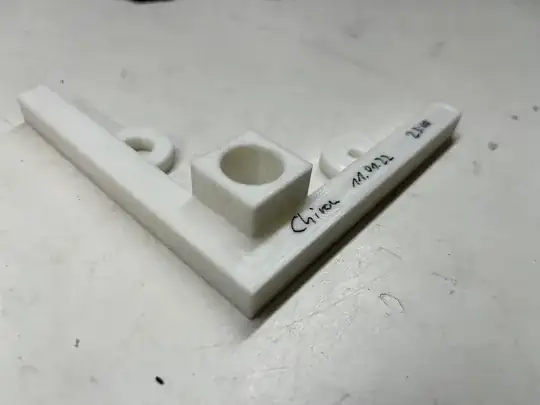

I have an Anycubic Chiron 3D printer without any technical modifications. For calibration purposes, I created a specific design that allows for measuring longer and shorter lengths as well as the diameter of holes. I mainly did this because an error in the settings of steps/mm will be more visible on a larger print and holes often came out too small for me in my prints. You can find pictures of my design below.

Now, I have three other printers (Artillery Sidewinder X1, Tronxy X5SA-400, Geeetech A30T) that print the model OK. Whenever there is a problem with the X- and Y-steps/mm setting it will be equally visible on the shorter "calibration cube" part of the model as well as on the longer parts. While for the latter 3 printers this expectation holds true, the Chiron produces different results.

If I calibrate the steps/mm for the Y-axis based on the long side correctly, the calibration cube part is off by about +0.2 mm. Of course, if I calibrate the steps/mm based on the calibration cube part, the long side is too short. This really confuses me as I would have expected that a potential error would be visible on both parts of the model.

The error can be observed consistently. The prints come out OK, just the measurements are off.

My first guess was that it might have something to do with the extruder, but I calibrated the extruder several times already without luck. My second guess would be that it might have something to do with the nozzle size not being accurate. Last not least, maybe some steps could be missed consistently by the motor on longer lines because the stepper voltage is not correctly set? I'm just speculating...

I already checked the belt, belt tension and the pulleys. It is also not important on which part of the bed I print. I also replaced the stepper drivers (A4988) by TMC2208 drivers as I had these available from another project. No luck, though, same result with the new drivers.

Any help/hint is appreciated.