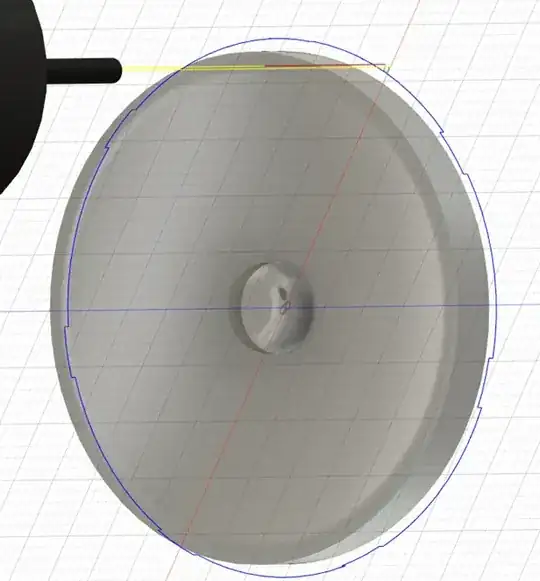

I have a 3018 Pro CNC and being trying cutting a contour of a simple circular part:

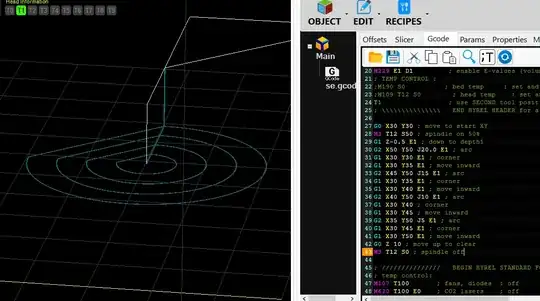

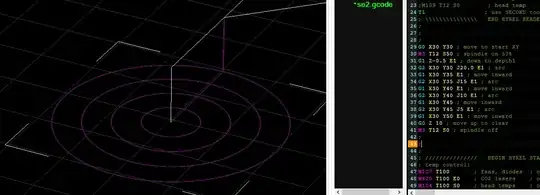

G-code:

(TestKnobContour)

(T1 D=1 CR=0 - ZMIN=-3 - flat end mill)

G90 G94

G17

G21

G90

(2D Contour1)

Z15

S5000 M3

G54

G0 X10.8 Y0.1

Z15

G1 Z5 F10.0

Z1 F10.0

Z-2.9

X10.792 Z-2.938 F10.0

X10.771 Z-2.971

X10.738 Z-2.992

X10.7 Z-3

X10.6

X10.562 Y0.092

X10.529 Y0.071

X10.508 Y0.038

X10.5 Y0

G2 X9.851 Y-3.634 I-10.5 J0

G1 Z-2.75

G2 X8.983 Y-5.436 I-9.851 J3.634

G1 Z-3 F10.0

G2 X3.301 Y-9.968 I-8.983 J5.436 F10.0

G1 Z-2.75

G2 X1.351 Y-10.413 I-3.301 J9.968

G1 Z-3 F10.0

G2 X-5.735 Y-8.795 I-1.351 J10.413 F10.0

G1 Z-2.75

G2 X-7.299 Y-7.548 I5.735 J8.795

G1 Z-3 F10.0

G2 X-10.452 Y-1 I7.299 J7.548 F10.0

G1 Z-2.75

G2 X-10.452 Y1 I10.452 J1

G1 Z-3 F10.0

G2 X-7.299 Y7.548 I10.452 J-1 F10.0

G1 Z-2.75

G2 X-5.735 Y8.795 I7.299 J-7.548

G1 Z-3 F10.0

G2 X1.351 Y10.413 I5.735 J-8.795 F10.0

G1 Z-2.75

G2 X3.301 Y9.968 I-1.351 J-10.413

G1 Z-3 F10.0

G2 X8.983 Y5.436 I-3.301 J-9.968 F10.0

G1 Z-2.75

G2 X9.851 Y3.634 I-8.983 J-5.436

G1 Z-3 F10.0

G2 X10.5 Y0 I-9.851 J-3.634 F10.0

G1 X10.508 Y-0.038

X10.529 Y-0.071

X10.562 Y-0.092

X10.6 Y-0.1

X10.7

X10.738 Z-2.992

X10.771 Z-2.971

X10.792 Z-2.938

X10.8 Z-2.9

G0 Z15

M5

X0 Y0 Z0

M30

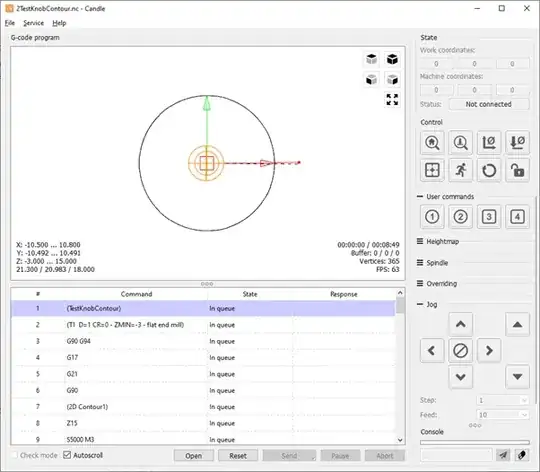

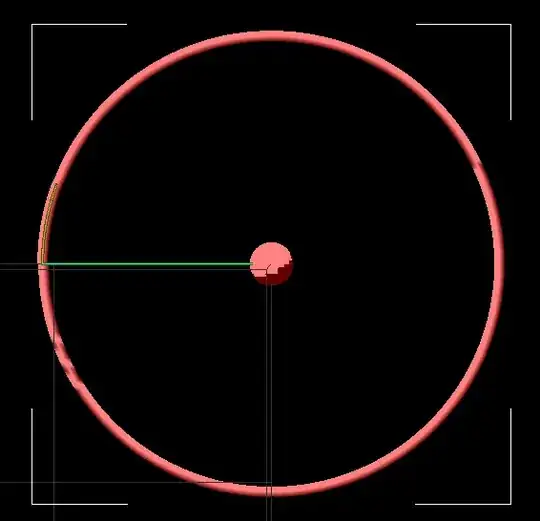

Candle shows that everything is fine for this G-code:

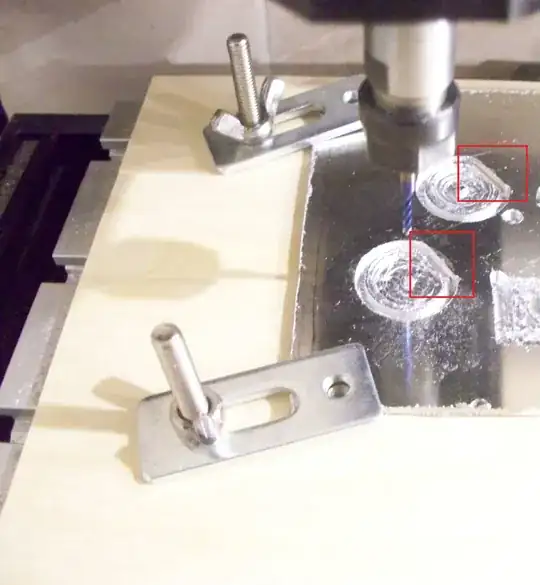

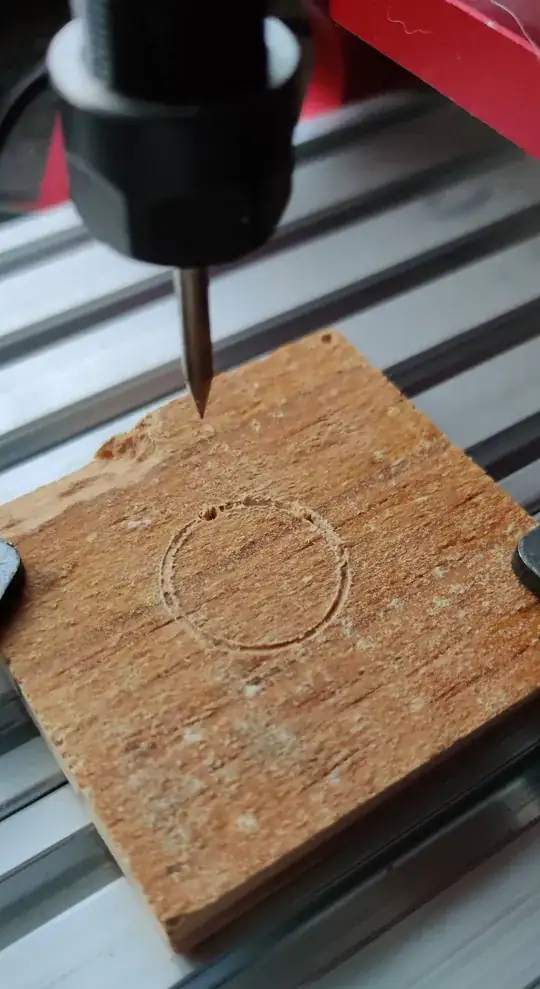

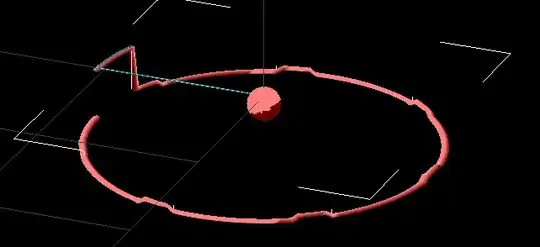

However, I am getting weird results (see top right):

What can I do for troubleshooting?