I am new to 3D printing and have an Ender 5 Pro.

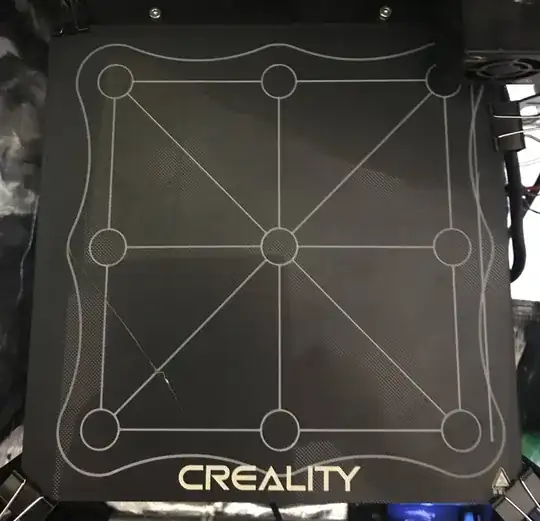

I have manually leveled the bed by setting the nozzle gap to 0.1 mm (via feeler gauges) and then printing a calibration print and manually adjusting the bed height as it prints. I can get perfect calibration prints using both a glass bed and a PEI bed, printing with a bed temp of 75 °C and a nozzle temp of 210 °C:

I’m now trying various other prints without success, as the print doesn’t adhere. See this example of a 1 mm thick bookmark, which I am printing with a brim to try and help :

I’m not sure what the experts here can ascertain from this failed print without all the slicing parameters. I’m a bit suspicious that the print appears to clump and I’m wondering if the soft extruded material is sticking to the PLA already laid down and if so, if I can address that?

I actually seemed to have more success with the original flexible bed with several successful prints.

The G-code for the calibration target: https://pastebin.com/Brc8R8Cs

and for the bookmark: https://pastebin.com/9AXaqiMw

I had to remove a lot of the G-code for the bookmark due to its size, so hopefully I've left the important stuff in.

I started printing by loading the models in CURA, slicing and exporting to an SD card. I didn't;t create a new project for each print and it took me a while to realise I was losing the slicing parameters I'd used each time, making it difficult or impossible to go back and just change one set of parms. I'm now creating a separate project, so hopefully from now on I can just tweak one or 2 parms.