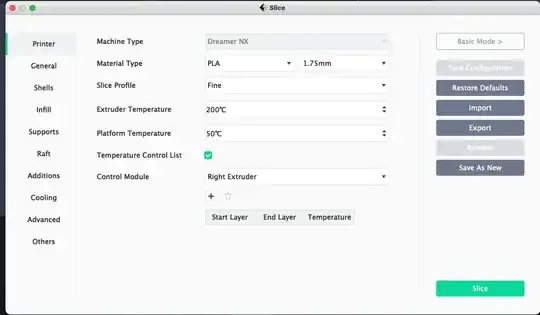

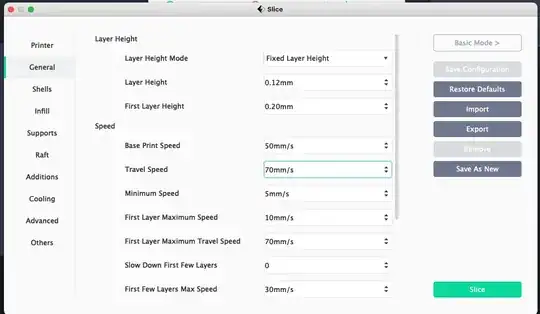

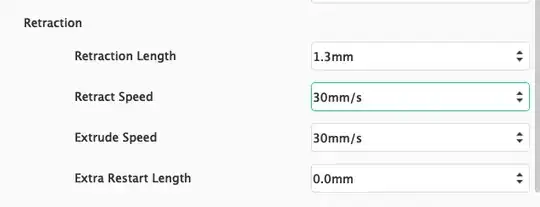

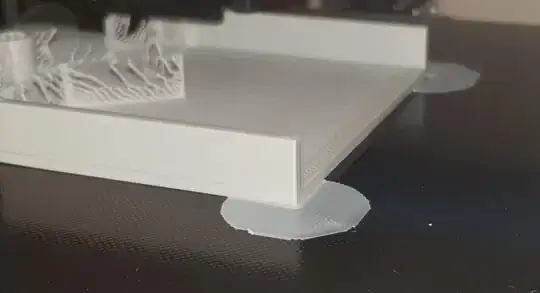

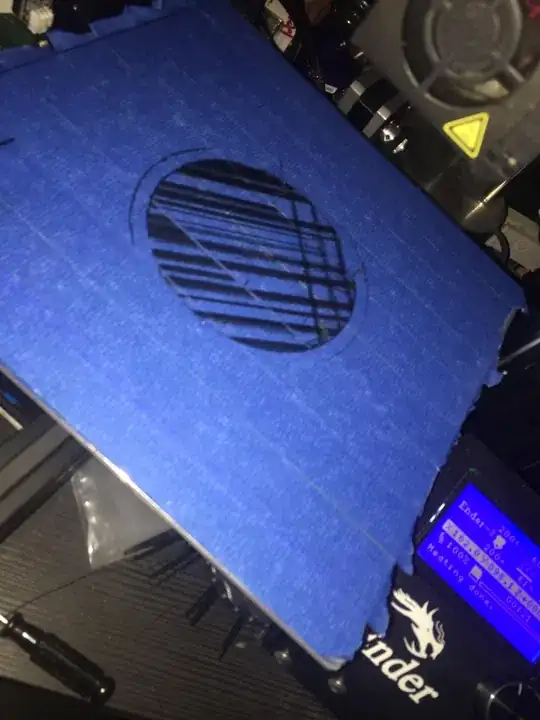

The cause of the meshing is under-extrusion. When under-extrusion happens, several problems can cause this. E.g. heat creep (probably not the issue here because heat creep is usually not recoverable, but not unimaginable since this is an enclosed printer, you could try printing at a lower temperature and look into less aggressive retraction settings), or an extrusion problem.

Since this is an intermittent, recurring defect, this could typically be a result of spool entanglement or any other defect in the extrusion path. Once the entanglement or friction on the spool has resolved itself, the print continues as if nothing happened.

You should print again and look at what happens. Also pay attention to the extruder, it may be skipping steps or hasn't got enough force to push the filament through.

Check the extrusion of filament also by disconnecting the extruder and manually feeding the filament through a hot nozzle. It should be easy to push the filament through the nozzle at temperature. If not, try cleaning the nozzle doing a cold/atomic pull (feed filament hot, cut the power to the hotend, wait until the temperature drops considerably and suddenly pull out the filament, preferably with nylon or cleaning filament or any other high temperature filament).