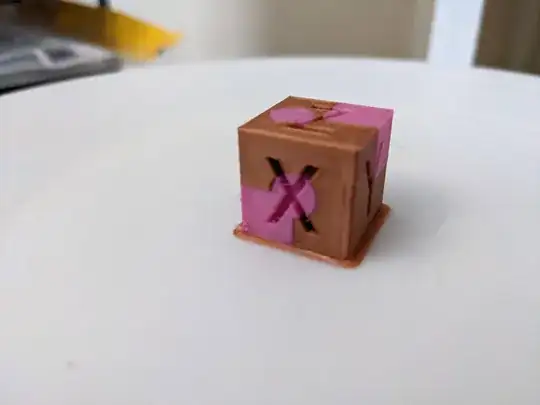

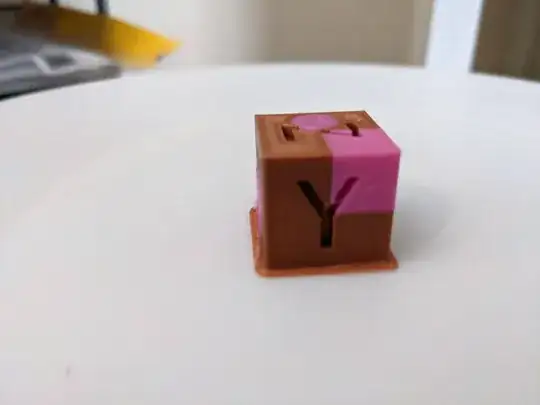

Recently got a Creator 3 (v2) and single-colour prints are great, but dual colour Benchies are coming out quite bad. Initially, I thought it was X/Y calibration as when I printed a dual-colour cube, I could feel a slight bump as I ran my fingernail across the joins. I tweaked that and the cube now seems good (pics attached), but the Benchy came out the same, with a lot of scruffy plastic in several places.

I had the same with some old Balco filament and now with Technology Outlet filament (all four reels have printed fine on their own, the prints are really good).

I'm using Flashprint 5.1 for slicing, with mostly default settings (though infill reduced to 10 % and temp increased from 200 °C to 210 °C for the Technology Outlet filament). I'm using an Ooze Shield and a brim. Stock 0.4 mm nozzles.

Any suggestions on what the issue might be or what I can do to improve it some? The dual-colour pic on the Benchy website looks way better, so I don't think it's just that these parts of the models are difficult to print.

Thanks!