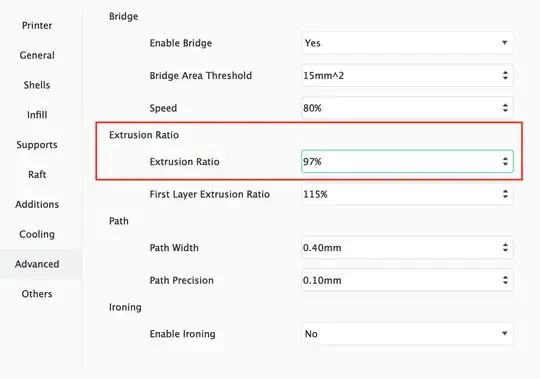

In FlashPrint there is an Extrusion Ratio setting. It's set to 97 % for the stock PLA profile and 107 % for the stock PETG profile.

I would've thought these would be 100 % by default (and the same for all materials). Why is it that these defaults make sense and they differ? Why would you need to push more PETG for the same print than PLA if they're the same diameter filament?