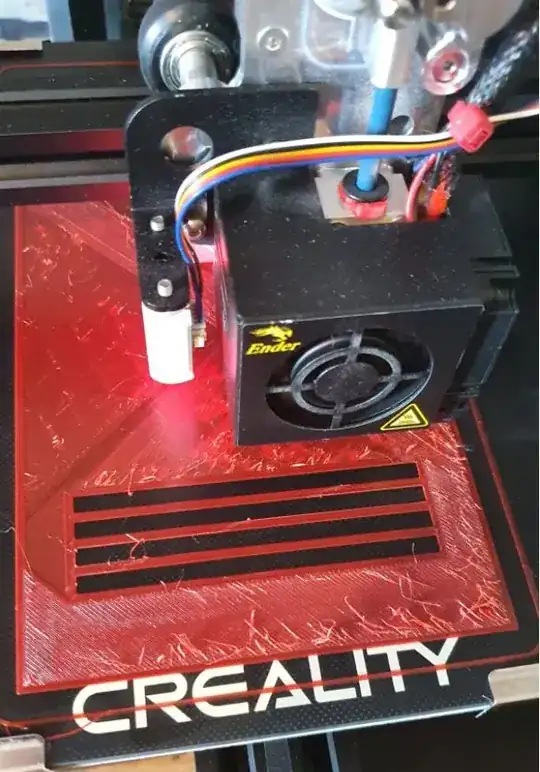

I'm getting a lot of blobbing and scuffing on top of my prints in PETG on my Ender 3 with AMH/DD. It doesn't seem to do this if the print doesn't have a flat bottom so much.

I have the E-steps set to 130, which if anything is slightly under extruding vs the caliper measurements.

Any ideas how I can fix this?

Cura settings:

[general]

version = 4

name = Creality Ender 3 - eSUN PETG - Red

definition = creality_base

[metadata]

type = quality_changes

quality_type = standard

intent_category = default

position = 0

setting_version = 17

[values]

cool_fan_full_layer = 3

infill_overlap = 15

infill_pattern = triangles

infill_sparse_density = 10

ironing_enabled = False

ironing_only_highest_layer = True

material_print_temperature = 230

retraction_amount = 2

retraction_speed = 25

skirt_gap = 6

speed_infill = 30

speed_print = 35

speed_topbottom = 15

speed_travel = 250.0

speed_wall = 25

wall_line_count = 3

z_seam_x = 150

z_seam_y = 300

----

[general]

version = 4

name = Creality Ender 3 - eSUN PETG - Red

definition = creality_base

[metadata]

type = quality_changes

quality_type = standard

setting_version = 17

[values]

acceleration_enabled = True

jerk_enabled = True

layer_height_0 = 0.21

material_bed_temperature = 75

material_bed_temperature_layer_0 = 75