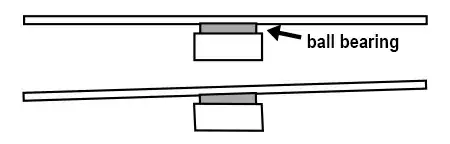

I have a Tevo Flash. Normally, I don't care about perpendicularity with respect to the table. But now I have a 5" disc on a ball bearing, held by a 3D printed tube with a flat bottom. If the tube's axis is not 100 % perpendicular to the bottom, the disc, when spun, wobbles at the edge: ~1/8".

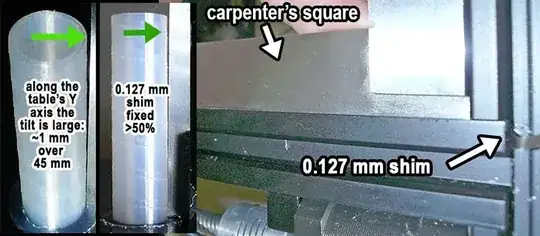

As a test, I printed a vertical sample tube. I took close-up pics, on the printer's table, next to a carpenter's square. Down the table's Y axis, there's a vert. deviation of ~1 mm over 45 mm of height, between the sample tube and the square. Down the X-axis, the deviation is small.

How do I deal with it? Can a slicer (I have Simplify3D) compensate for it? I could gently "skew" the geo in 3D modeling software, but it seems inelegant.

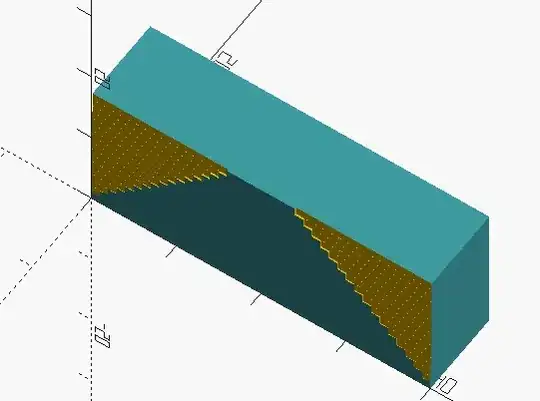

Note: this has nothing to do with bed leveling. The bed is level, the printer has a BLTouch. The first layers look great. The problem is above the bed. The right angles of the aluminum-extrusion frame aren't 100 % exact. Measured with the carpenter's square, the vertical columns of the frame (Z) deviate 1-2 mm over 100 mm from perpendicular, with respect to the bottom frame (X-Y). Trying to fix the whole frame would be hard.

EDIT: I used a 0.127 mm shim (from a sacrificial steel gauge blade), it fixed most of it. With the printer laid horizontally (so I could work with the screws underneath) and the shim in, the vertical posts were 100% true (see pic). When I put the printer back into its vertical, working position, the posts tilted back a bit. I'll try a 0.15 mm shim.