A clear answer is not available, since no one performed a proper test as of June 2021.

The closest answer I can provide is that damping feet result in a change of vibration behaviour, as discussed in this Klipper issue report. How it's not clear.

I paste some of the findings:

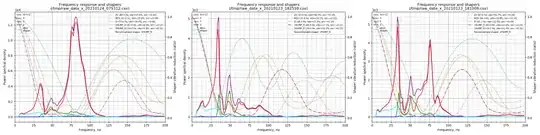

I took several measurements with different configurations and the

results are quite surprising IMO. The following graphs show the

respective vibration results for (from left to right):

1- The retrofit back to the standard hard rubber feet

2- The printer

only standing on the "feet clamps" as shown in the picture above

3-

The printer standing on the "feet clamps" but with squash balls

inserted

X-Axis

Configuration 2 vs 3:

The damping is causing an additional spike at ~76 Hz;

Power-Spectral-Density is roughly the same;

Overall vibration is a bit lower in the damped version (11.4 % vs 16% @ 3hump_ei) --> Probably due to damping the additional spike;

A bit surprisingly the shaper recommendation is identical

Configuration 1 (original feet) drives Power-Spectral-Density from e3

range to e4 range

Configuration 1 brought back a dominant spike at

around 75 Hz to 80 Hz (which was surprisingly gone with the printer

sitting on the hard and small area of the "feet clamps"

Configuration

1 nearly tripled the spike at 75 Hz to 80 Hz compared to No. 3

(Power-Spectral-Density 12,000 vs 4,200) The spike at around 30 Hz

stayed pretty much the same

Y-Axis

The effect on the Y-axis is pretty small

My conclusions

The resonance effects very much depend on the type of feet

For

whatever reason every damping in the feet resulted in worse vibration

If you want to know more about it, install Klipper and an ADXL345 accelerometer, make measurements, write a blog post or post here in a new answer.

I may be able to do it within within the year. It's a loose deadline, yes.

I have a printer on a wobbly table, but I haven't performed measurements yet.

I expect it to be better than a stiff table, since part of the energy is dissipated by the table and not by the printer frame (we are not talking about independent feet, but table as a whole), resulting in better quality at high acceleration. Of course if your printer runs at 500-1500 mm/s^2 you won't see anything. If you run at 5000+ mm/s^2, then...