I have been using an Anycubic i3 Mega for about a month now and it worked fine. But when I designed a simple model in Fusion 360 and sliced it with Cura it started to have issues sticking to the bed. I thought the problem was the model so I tried to print a Benchy, but the same problem occurred. I readjusted the bed but it's still not working. I'm not sure how I can trouble shoot this.

-

Hi, welcome to 3DPrinting.SE! I removed reference to Fusion files in the title, that appears not to be the issue from the question body. Basically, your filament fails to adhere, this can e.g. be caused by not enough temperature of the bed, not clean but greasy or dusty bed surface, incorrect nozzle to bed distance, the filament type or the geometry of the print. – 0scar Mar 06 '21 at 10:50

-

try hair spray or a glue stick on a clean surface – MeSo2 Mar 11 '21 at 00:36

3 Answers

The proper answer could be not related to Fusion, as you already noticed.

I suppose the issue is that the Ultrabase surface (or any other glass surface you have installed) was not cleaned during the first month? So it should be cleaned from grease and possibly dust. The general cleaning method is to use isopropyl alcohol (IPA) from time to time (btw. I am curious if it is advised in a printer's manual). If it does not fully help, I suppose using a dish soap with hot water prior to IPA is good step. Though I do not own this bed, so could not be 100 % sure of impact. (Definitely do not use any extra adhesion helpers for Ultrabed, because it has some specific microstructure which will get stuffed.)

You could want review other threads like this How to get Sunlu PLA to adhere to the printing bed? to get other hints and supplement your checklist. One thing to check first (and regularly) is proper bed levelling at current moment - and compare to initial layer settings in Cura (thickness, width, flow percentage).

-

1Thanks for the advice! I found that slowing down the first layer helped it to adhere better. But I will also clean the bed more regularly – leowrites Mar 07 '21 at 17:26

Keeping the print bed clean as mention in other answers is key. Dish soap (without any additives) and water to wash away oils from your hands the printer itself is the first step. Isopropyl Alcohol (IPA) is also good to keep the bed clean between prints, but when you run into adhesion problems, wash with soap first. IPA in many cases just move the oils around the bed instead of removing them. Also, always wipe from the centre of your bed to the outside.

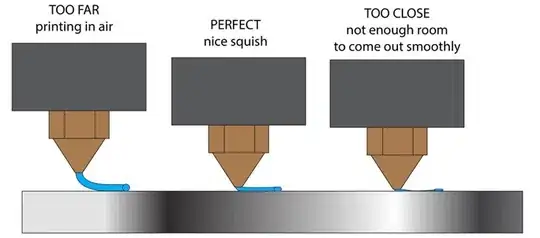

The next step is to also ensure the bed is level (unless you have auto-levelling). If the bed is level, then you need to make sure your z-offset is correct. The first layer must be printed with the nozzle low enough to press the first layer into an oval shape onto the bed so that the surface area in contact with the bed is increased. If the z-offset is too high the first layer filament is going to have a round shape which means the printer is basically printing in the air.

Be careful not to decrease the z-offset too drastically because the nozzle should never come in contact with the bed because damage to the bed, nozzle or heat-break is possible.

- 262

- 1

- 8

A "hack" I used was to print with a raft. I decreased the width of the raft in Cura so I'm not printing with excess plastic and the raft ensures my print always sticks.

Another thing to look at is to look at the print speed, a slightly slower speed might help with the build plate adhesion. This is something I noticed from printing with a raft

For reference, I print with a glass bed and the plastic failed to adhere to the bed even after washing it and using sanitizer to clean it off. IPA is the real deal though but I didn't give it a try.

- 11

- 1

-

I have reverse experience with sanitizer, in my case it made things worse. But some other hint: I read once to use slaty water. For few weeks I continue to do it on my old printer with clean glass bed: after soap-washing I heat the bed, and then apply strong brine. Quickly formed crystals have form of dust, which I loosely wipe with hand tissue. (And slowly, because I am afraid of this salt dust against linear barrings.) In my opinion it helps with adhesion, though I am not sure why. – octopus8 Mar 08 '21 at 20:33

-

I'm guessing the rough surface that the salt creates on a microscopic level provides adhesion points for the plastic. That sounds like an "if all else fails" type of solution though since that might scratch the glass surface – Pelumi Mar 08 '21 at 20:37

-

A raft should be the final resort if everything else fails, e.g. with high shrinkage, high temperature filaments. An adhesive is usually a better solution, nowadays there are specific print adhesion sprays. The bottom layer finish will benefit from it. – 0scar Mar 08 '21 at 22:10