After a year of printing smaller models, I finally went to print something that would take up most of the build plate from left to right and realized that my nozzle cannot reach "true" X home.

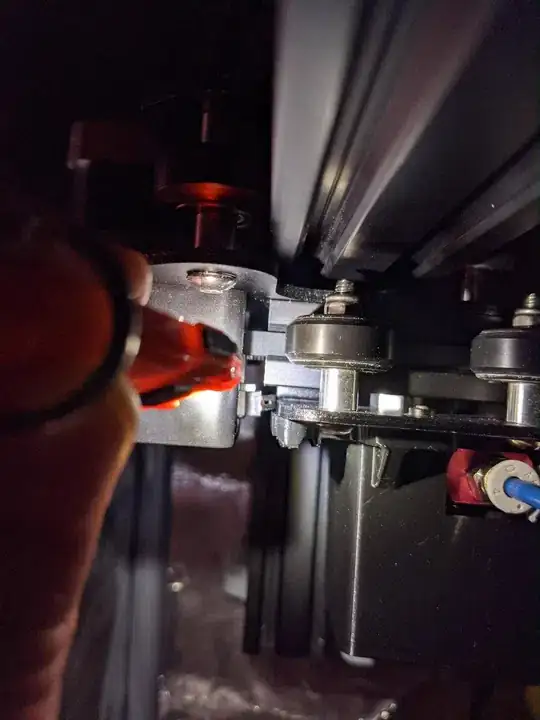

As seen in this picture:

the X-axis endstop does not allow a true X0, thus losing me precious mm of print space! I over-exaggerate, but truly is there any way to shift the X-axis more to the left or the Y axis/build plate more to the right to gain full bed usage?

the X-axis endstop does not allow a true X0, thus losing me precious mm of print space! I over-exaggerate, but truly is there any way to shift the X-axis more to the left or the Y axis/build plate more to the right to gain full bed usage?

Additional photo showing that the actual hotend plate is hitting the endstop:

Is this an Ender 3 problem in general that I have missed in my internet searches on this or is it just a manufacturing lottery that I unfortunately lost?