When trying to solve the issue described in this post I followed the advice in the accepted answer and I found that the timing pulley holes for the Y axis (to "secure" the pulley to the motor shaft) were only half drilled (!!!). I suppose that everything worked fine (even without blind screws) for the first month (probably because the belt was extremely tight) but just a bit of wearing and it started to slip.

While I already replaced the pulley I also contacted the Creality technical support to obtain (at lest! funny...) a reassurance that it didn't possibly stressed the belt or the bearing balls. My experience with their technical support has been horrible and I am still waiting (after weeks) my answer (probably it's easier for them to try to ignore their sloppy assembly and QA) but they sent me a procedure to follow to "debug" any issue with my printer.

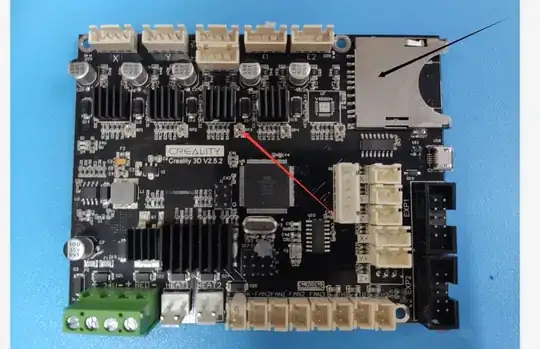

One of the pictures in that procedure is this:

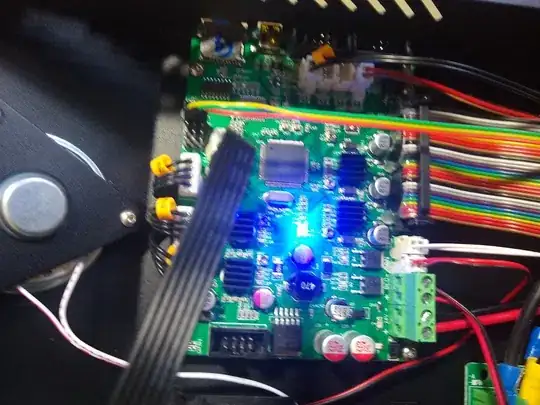

To my surprise this is the motherboard I have:

Now I am puzzled. Which one is the correct motherboard for the Creality CR-10S Pro V2 (not the old version but the newer V2)? Is this just [another] sloppy mistake from the technical support or I do have the wrong motherboard? Differences with V1 are not many then I suppose it could even work with the old one...