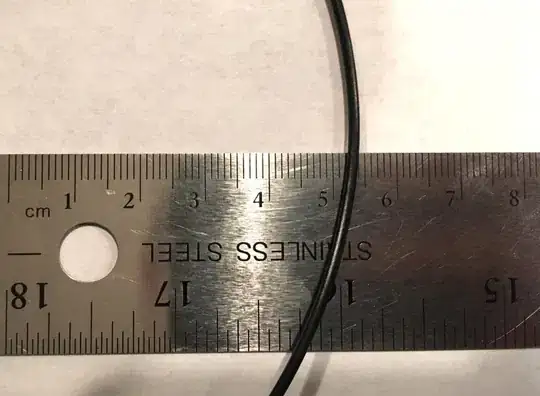

I had a new Extruder tip on my Ender 3 3D printer. the tip looked like the left tip in the below image. After I have been using it for about 5 months, the tip got dull/flat, like the tip on the right in the below image.

The only filament I have used is a spool of PLA (from hatchbox) and a spool of PETG (from sain-smart)

About the Filament

From the time that I replaced the tip, to now, i have only used my 1 spool of PLA filament.

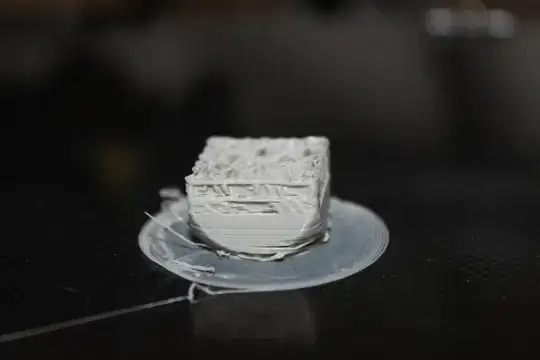

I don't believe it has any carbon-fiber in it, the only other things I can think of, are that the filament has a tough time sticking to the bed, so I have to print pretty close to the bed.

Image of my 3D prints using my PLA filament

I don't 3D print a terribly large amount, Is it normal to have to be replacing the pen this often?

How do I prevent my extruder tip from getting dull so soon? Is there a way to prevent the pen tip from getting dull at all?

Actual Images: (Sorry for all the edits, I’m trying to add the images on my phone and it’s not working)