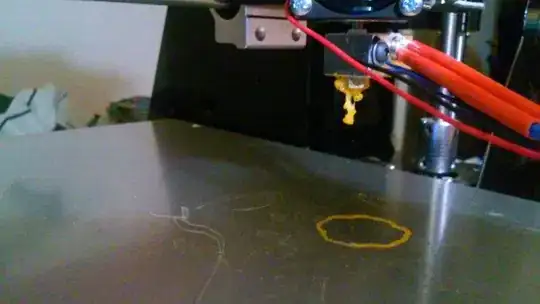

I am using the E3D v6 hotend with the titan extruder. Everytime I go to do a test print, just enough stringy filament oozes comes out of the hotend "right before" it lays down the first layer. I have no idea why it oozes out the little bit of filament before it prints.... The unwanted filament builds up while some of the first layer is done. As a result, what has been printed or about to be printed get stuck together as it tries to do the rest of the print....

-

Hi, Chris! What filament and temperature are you printing at? FYI, this is common for bowden pinters: my bowden printer also oozes as the hotend heats up due to the *hystiresis* (or "spring effect") of the bowden tube. I do not know if the Titan extruder could be susceptible to this since it isn't (?) bowden. – Tormod Haugene Jun 29 '16 at 05:47

-

Maybe you could post your start G-code (and a bit of the first layer) so we can see what your printer is actually doing. – Tom van der Zanden Jun 29 '16 at 07:14

-

Hmm, just to be sure, do you mean the plastic is oozing from the tip of the nozzle (normal) or is oozing out from between the nozzle and hot block? – Ryan Carlyle Jun 29 '16 at 14:15

4 Answers

As the filament in the melt chamber heats up, it's going to inevitably ooze a little bit. Make sure you watch for this and clean it off as the hot-end heats up, and setup you slicing software to print a skirt, which will print a few loops around the outside of your print, separated by a few mm, to deal with ooze and get filament flowing properly.

If it oozes a lot, try reducing your print temperature a bit.

- 116

- 2

-

I would even say it's good to reduce temp as a first step, then when ozzing is slightly reduced you could consider skirt as Ian Williams said. Why? It's because skirt is time and material consumming, so it's better to have as less skirts as possible (if it's used only to stabilize extruding process) – darth pixel Jun 29 '16 at 11:05

-

1The material and time used when printing a skirt are negligible. It's better to stabilise the extruding process to make sure your first layer is good, than to worry about a few seconds of time and a tenth of a gram of plastic. – Ian Williams Jun 30 '16 at 12:09

-

He he - I fell I misdescribe it. Of course it's good to have stable extrusion but as the temperature is too high the first step is to reduce it so it won't ozzing that much. Heavy ozzing is a signal that there is something wrong so reducing temp is to fix it and when it's fixed then it can appear that many skirt loops is unnecessary. Let's say - you can first patch the tire and then remove the nail but it's better to do it in the oposite order ;) – darth pixel Jun 30 '16 at 12:50

One possible solution is to "park" the hotend on the print bed as it is heating up. The bed blocks the nozzle, and prevents ooze from coming out. If any does come up, it tends to stick to the bed, not to the nozzle. You can do this by including an appropriate G1 command in your start G-code.

- 14,588

- 2

- 33

- 60

In general, it's a bit normal to have some filament ooze during warm-up. However, if it seems to be an abnormal amount, you may want to consider reducing your target temperature.

Keep in mind that ideal extrusion temperatures are subjective to the source of your filament. Not all filament is of the same material quality and differing degrees of purity. Sometimes, the same filament will be of different quality from the same source. It might be worth dedicating the first bit of each spool to a bar test to determine what the appropriate extrusion temperature should be.

A simple test would be to use the control panel on your machine or use your software (whichever is easiest for you):

- Manually set the extruder to extrude filament

- Stop the extruder

- Clean excess material from nozzle

- Watch for ooze

- Gradually reduce the temperature

- Repeat until the amount of ooze is an appropriate to your liking

Also remember that there will be some left-over material from a previous spool when swapping spools.

- 6,234

- 2

- 18

- 40

As others have said, printers ooze when heating up. I keep a business card by the printer and do a wipe on the nozzle just before it starts the print.

- 96

- 3