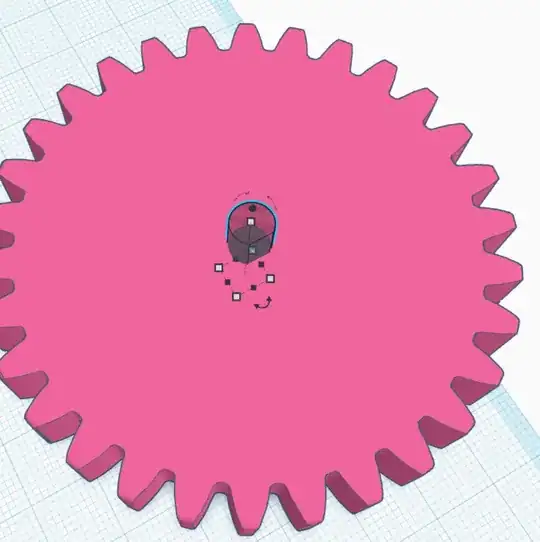

I am currently trying to print a gear with the possibility to connect it to the shaft of a DC motor. The following picture best describes what the shaft of the motor looks like by showing the hole printed in the gear:

So far this works well for a short amount of time, however since the gear is connected to another gear that is from time to time exerting quite some resistance already after a few revolutions the shaft starts to wear out the material that is holding it and it turns without powering the gear, i.e. the printed part is not strong enough to withstand the torque of the motor.

I am wondering what the best way forward would be here. I see multiple options:

- Design a different connection to the shaft, however I don't know of any

- Switch to a different material, I am currently using PLA, but I could also go for ABS or PETG if any of them would provide advantages. For PLA vs ABS I found some conflicting information which one is "harder"

- Play with the parameters of the print. At the moment I am only using 3 wall layers, I wonder if increasing the number of wall layers would improve rigidity.

Are there other ideas? What could you recommend me to improve this connection?