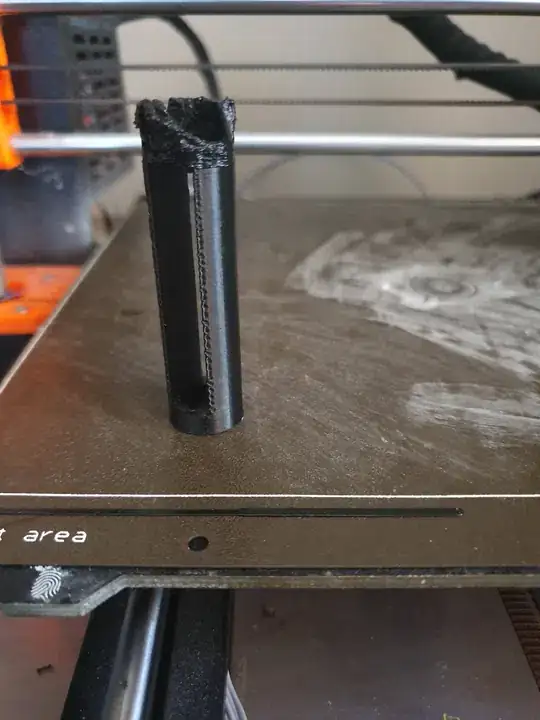

I'm using Prusa i3 MK3S and every time I want to create a durable, impact resistant part, I use ABS/Nylon. The problem is, however, that when I print something small (of less than 1 cm width for ABS, less than 2.5 cm for Nylon), the print deforms, shrinks, loses shape as shown on the image (the top). Also, the quality is far below my expectations (I am using a kit, but still I get better print quality on my Ender 3).

My settings:

- Nozzle 250 °C

- Bed 115 °C

- Fan turned off and 50 % for bridges

- Layer Height 0.15 mm-0.3 mm

The settings are the same for Nylon and ABS. I am using a textured sheet.

I know that enabling cooling/decreasing the temperature would partially fix this problem, but that would drastically decrease the strength of my parts. I am not using normal ABS, the name of my filament is ABS-702, designed for printers without an enclosure.