The way you're thinking about using the LCD directly on the bottom of resin vat and cure the resin is a good idea, but there are several problems that I will focus on the main. as mentioned by @Trish some issues might occur to the LCD and u need to replace it. Except that you need to clean the vat some times after print and with LCD attach to it, you know...

But the main reason is that when the resin is cured in the bottom layer can stick to the bottom of the vat so the printers have a solution to raise the bed and again lower it.

The FEP (Fluorinated Ethylene Propylene) membrane is an elastic material, so when the bed raises the FEP film get raise a little sticking to the part and detaching. so we cant have this situation with the lcd because the lcd is a solid film that bends just a little.

I'm also working on an LCD resin base printer so please post questions if you have any other questions.

? Will the display break when printing? what are the risks?

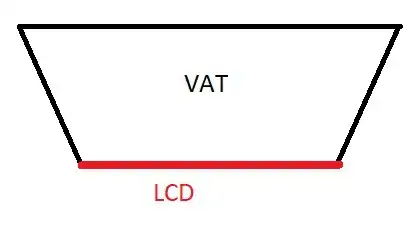

I seen a lot of printers and all of them use PP material for VAT bottom and attach with a lot of screws. I want make more simple VAT-LCD constructions and I think this construction transmis UV light better

? Will the display break when printing? what are the risks?

I seen a lot of printers and all of them use PP material for VAT bottom and attach with a lot of screws. I want make more simple VAT-LCD constructions and I think this construction transmis UV light better