If the tube is PTFE, the tube is not likely to be melting unless your hotend temperature is out of control. You would probably notice the PLA cooking.

So, perhaps they aren't PTFE, or perhaps it is wear.

If it wasn't PTFE, you should be able to tell by the texture, slipperiness, and bending force.

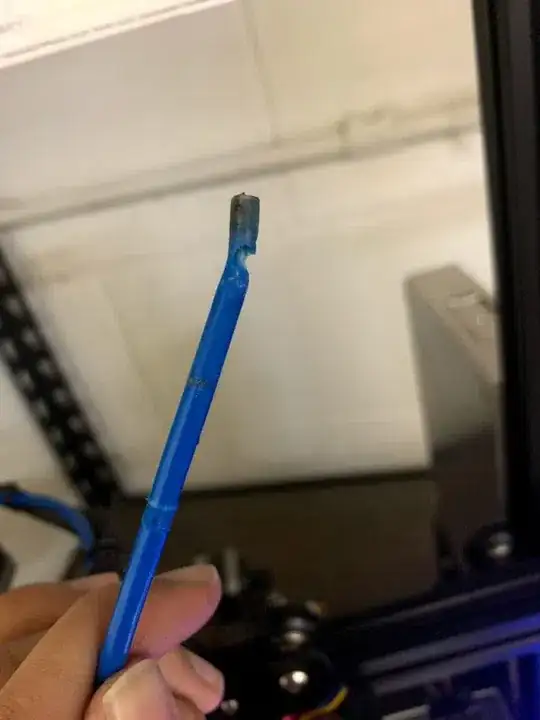

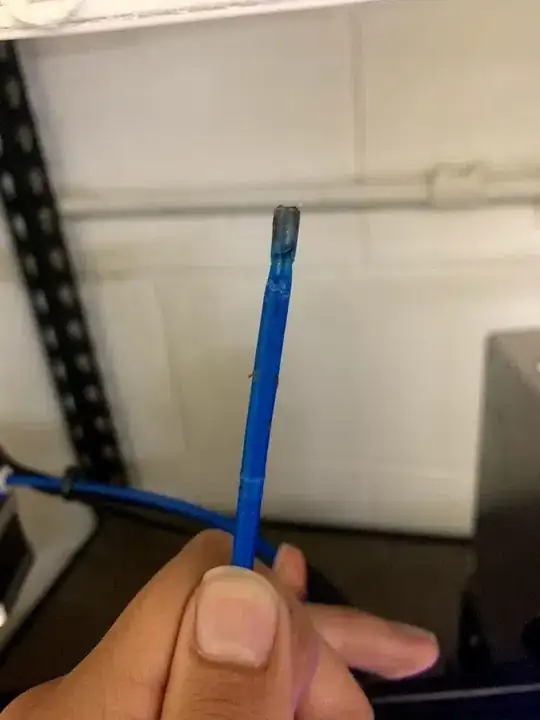

The four thinned faces look like they would correspond to four of the barbs in the connector. The thinned ring below the four thinned faces look like a wear line where the tube is pressing against the exit of the connector. It looks to me as if the tube is moving or flexing in the connector. The barbs act as little chisels cutting into the tube, which is how they restrain such a slippery material as PTFE.

It might work better if the tube were a little longer. This might reduce the forces at the limits of movement which may be placing strain on the tubes. If you can, you might also fashion a strain relief for the tube so that it doesn't bend right as it exist from the connector. If you can cut down on the movement, you will help with the external wear.

It is also possible that the tubes are being strained by a high filament pressure. All the drive to push filament into the hot end is matched by an equivalent reverse pressure from the tube onto the connector. If you can stand a higher print temperature, the life of the tube may be increased.

@towe added a comment:

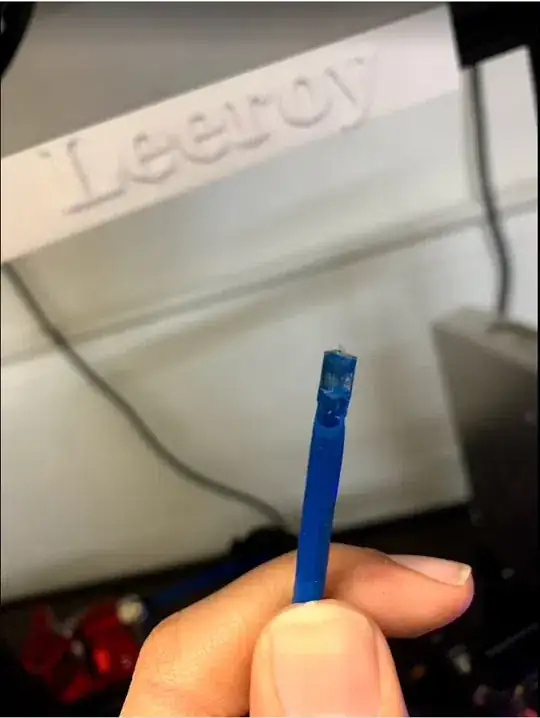

I don't think those are marks from the teeth of the pneumatic coupler. The questions states "where it pushes against the nozzle", and the Ender 3 Pro seems to have a hot-end where the Bowden tube reaches all the way through the cold end and heat break to the nozzle.

A mechanical drawing of what may be a MK-10 hot-end as used on the Ender 3 Pro also suggests that the Ender 3 Pro has a PTFE lined hot end. Lets accept that drawing as confirming that @towe is right. Never-the-less, the marks you show in the photo look like the types of cuts I have seen from a pneumatic coupler. How can we reconcile this contradiction?

The most direct answer would be that the tube is not reaching through to the nozzle. In the photo you don't show enough of the blue tube to show the coupler scars which should be a little further up the tube. Suppose that, in fact, the tube is not pressing against the nozzle. This might not be the case if any of these are true:

- There is a separate piece of PTFE that is permanently in hot end.

The Creality Ender 3 Pro looks as if

it is not configured for a Bowden feed. A PTFE lined hot-end for a

direct extruder would have a piece of PTFE cut to length in the

hot-end. A simple mod to make that a Bowden would leave that

sculpted PTFE tube in place.

- The pneumatic couplers have been replaced. Many couplers do not

permit the tube to pass through them, although the hole in the end

can be drilled to 4mm diameter. In fact, preventing the tube from

passing through a pneumatic coupler is a feature in the intended

application of coupling to air tubes in moderate pressure

applications.

- There is a bump in the path that is catching the tube and

preventing it from extending through to the cold end and onward.