Sound Encoding basics

Sound is a compression wave, and any depiction of it has to be an encoding of it. You can encode it so you can recreate the sound using a contraption that oscillates in the right way to compress air again in the right pattern, but you can't just "print it out" like you can scale up a lightwave from the nanometer scale to a visible one as a representation.

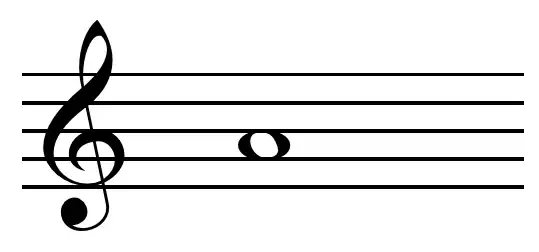

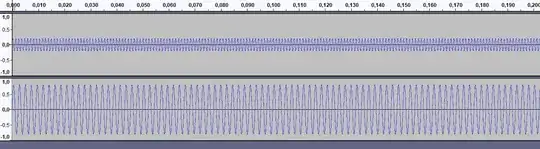

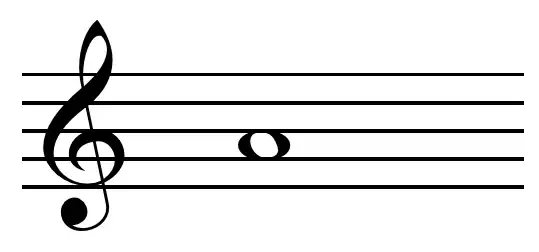

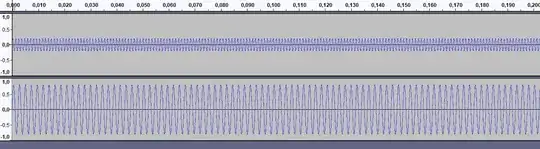

Let's take a simple example: a 440 Hz tune is generally considered to be the A4, aka concert pitch a or A440.

It could be encoded in a various ways. The probably oldest is to encode it as a note in violin notation, which then could be reproduced by anyone using a properly tuned instrument. The actual result depends on the instrument used as much as on the skill of the player. Each instrument thus might decode this encoded note differently, based on the physical setup of the instrument. Each instrument automatically creates the appropriate overtones.

In Midi, it is encoded as Note 69 and any machine that can decode a midi file could use this instruction, paired with an instrument to use, to create the A4 that is set for it. In Midi, the mere instruction of Note 69 does cut out skill, but how it sounds and feels comes from the instrument setup - which contains information about what overtones are to be created when playing this note.

For a physicist, the pure sound is encoded as just the notion of 440 Hz and some amplitude to balance how loud it is. With those instructions, he'd be able to set up a device that has these creates a 440 Hz tune. To generate the sound and feel of an instrument, the encoding for a physicist would need to contain all the overtones that are to swing with this one sound.

History of sound recording

Let's look at the very first way of recording sound: The Phonautograph of 1857 used a piece of paper or a sheet of glass blackened and then a membrane move a needle. When the plate would be moved, the needle left a written path. The encoding was done via 2 factors: the setup of the stylus (mainly how long is the arm) and the speed of the movement of the plate. Changing either changed the encoding. A longer arm would record a larger amplitude (making fainter sounds recordable) while faster movement would alter the timescale recorded, allowing to look at short instances and better compare them.

These vibration-pattern records could be used to measure and compare sounds but not be used to recreate the sound, as lines on paper nor scratches in soot are a good way to keep a reading needle in boundaries. it took till 2000 and the use of scanners as well as digital processing to recreate these recorded sounds.

The solution to recreate sounds was found by the Edison Laps in 1877 with the phonograph, which used a piece of thick tinfoil to record the motion pattern of the membrane. Again, then encoding was done via the arm setup and the speed at which the tinfoil clad cylinder moved (or rather rotated). It would till the 1880s develop to a wax cylinder, which was easier to inscribe and reproduce from. One such machine was used by Carl Orff.

The first Gramophone came in 1889, mainly altering the shape of the recording medium from cylinders to the well-known shape of vinyl records but made from hard plastics and shellac. Around 1901, a 12-inch gramophone disk held only a 4 minutes track, speaking volumes about the problems of encoding the complex patterns of sound onto a disk. At the same time, an Edison Amberol Cylinder held 4 minutes 30 seconds but would spin at 160 rpm. Soon after, celluloid would become the recording medium of its time, and the disk the de-facto "standard" as it was much better storable.

In 1925 finally, a real standard was developed to record at around $78^{+0.26}_{-0.08}$ rpm, which lead to only a 0.34 rpm difference between areas of 60 or 50 Hz mains voltage (though they needed different encoder rings), making records interchangeable between both machine types. All these recordings were encoded naturally: the vibrations of the membrane in the recording tool would be 1:1 transmitted to the vibrating stylus that would then do the encoding in such a way that a machine would reproduce what the recording one "heard" quite accurately.

When Vinyl came to the playing field as a recording medium at the end of world war II, so came a swap in the reading needle type: instead of a needle that would agitate a membrane directily, sapphire needles that would agitate an electrical pickup which in turn would activate a speaker. But while the recording technology advanced, the track length of a 12-inch disk was still limited to about 4 minutes at 78 rpm. It would only reach more than this in the last years of its use by applying LP technologies to pack the track tighter in the 1950s, achieving 17 minutes.

1948 came the LP, what we know as a classic vinyl record. At its introduction it could cram 23 minutes onto one side, making this possible by only using 33.5 rpm as the recording speed and thinner, much tighter coiled groves, increasing the information density by a factor of 5.75 for a 12-inch disk. 7-inch 45 rpm "singles" came out 4 years later. Within 10 years, the 33.5 and 45 rpm encoded variants had almost completely replaced the 78 rpm market.

Vinyl

As the history of analogous recordings shows, encoding a sound signal is rather easy in theory, hard in practice. A typical 12-inch LP Vinyl record of 20 minutes is a grove that is 427 meters long and coiled up 667 times. That means a single groove is between 0.04 and 0.08 mm wide - with an equally thin wall between. That means, that to achieve a printed phonograph record, you'd have to print accurately down to 40 microns to get an empty track. However, we also need to add the signal atop. And here comes the real problem:

An empty track has some 22 µm deviations, which the needle will usually not pick up at all. Dust, which creates the crackling at times, is in the same area (1-100 µm). The actual sound signal is encoded to have features as small as 75 nanometers. That is 3 magnitudes lower than the mere geometry of the grove, and equally much lower than any printer - including SLS - can achieve today, as 50 µm is often considered a lower limit in 2019.

To show how much tiny defects would ruin the sound quality, look at this rapid cast of a vinyl record. The resolution of the negative and the subsequently cast record is good enough to recognize the music, but the resin cast did contain so many gas bubbles that the noise level of the copy is very high.

Bonus: Unlike on cylinders the encoding of the signal on disks changes from the start to the end! The vinyl spins at a constant rate, but the radius from the center changes, leading in the speed on any part of the grove to be different as $|v|=|\omega \vec r \sin(\theta)|$, where omega is the speed in rad per second, theta is the angle of the reeding, so in this case, the sinus term becomes 1 and vanishes. This factor has to be taken into account for encoding so the pitch of the record doesn't change if the record is not created naturally by inscribing the signal onto a spinning disk.

Other encoding

Rumble Strips

However, it is quite easy to create a structure that creates sounds based on interaction with another body. Highway Sound Strips create sounds as the car tire bumps up and down, turning the car and tires into resonance bodies while the street "beats" upon it. In the case of a large percussion instrument like a car, we are talking centimeter scale.

Peg-Cylinder

A very simple method would be to go back to encoding and check out the note notation but limiting the length of notes to one unit. Encoding music this way results in pegs or ridges on a cylinder, which then can be used to actuate a mechanism to decode the music and create sounds like in a music box. In a music box of this kind, the demand for accuracy is about 3 to 5 magnitudes lower than in vinyl records: we speak about a tenth of a millimeter to centimeter scale.

Such a Musical box or noisemaker can be easily printed and is pretty much a rumble strip coiled around a cylinder. The length of the sample is determined by the resolution, playback speed and diameter of the cylinder while the complexity is determined by the rows of pegs of it: a noisemaker is pretty much a 1-note, high speed, music box. Typically, one rotation stores about 25 to 30 seconds. Typical examples would be the first part of Für Elise, or the Marble Machine (Between second 30 and 35 the encoding wheel rotates 1 fifth). Some barrel organs also use the peg method, like one can see here. With some trickery, one cylinder could be used to encode multiple parts that play one after another once a rotation is done by and silencing some parts of the machine depending on an extra encoder, like this 3-part Für Elise music box.

Hole-Plate(-strip)

A different method would be to encode the music as holes in a continuous strip and use air as a decoding method. If the air then gets directed into pipes, we have a street organ. Typically, one would use a paper strip as the encoded message, but it could be printed just as well, especially if one uses a setup that uses plates hinged to one another instead of a rolled-up paper as in this example. With such a way to stash away the extra length, the upper limit for music length rises from a couple of seconds to several minutes easily even with such a "bad" encoding.