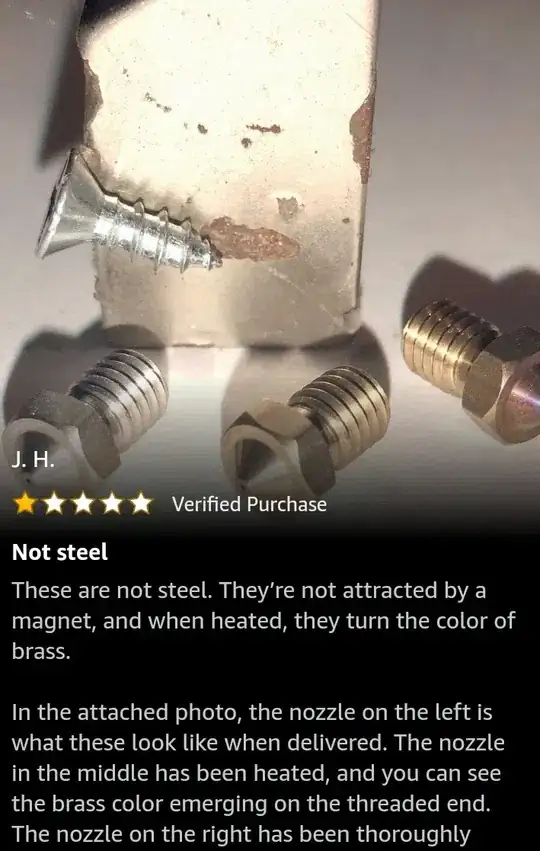

Let's preface, that there are a LOT of metal identification methods. For example, I found this guide helpful and I had been at the scrapyard lately, where I have been told that 90+% of the time, steel objects that are non-magnetic are the more valuable stainless steels. The kitchen sink I dropped off? Stainless, non-magnetic steel.

Tempering/Annealing behavior

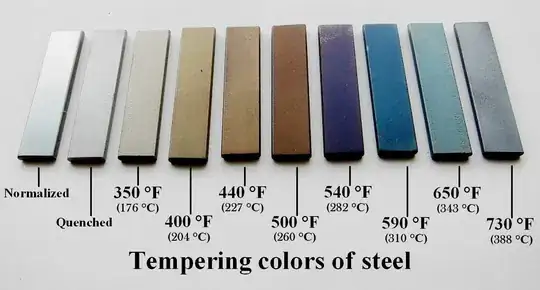

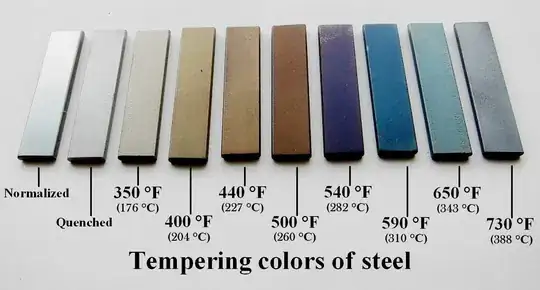

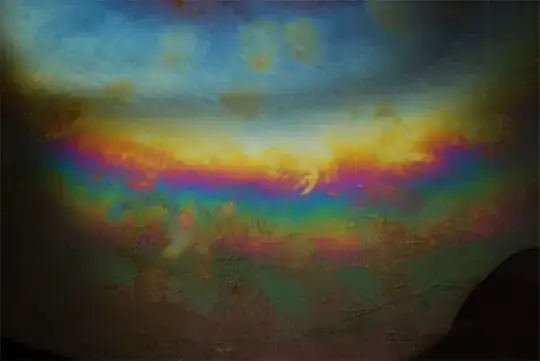

The very fact that the nozzles do change color to a brassy color that is commonly called straw is proof that it is indeed steel: heating up a piece of steel does alter the steel and also alters the surface color in a process called tempering. The color is only the surface, and the mild straw color would become orange-brown, purple, pale blue teal and yellow if you were to heat it higher. Take a look at the tempering colors of steel here:

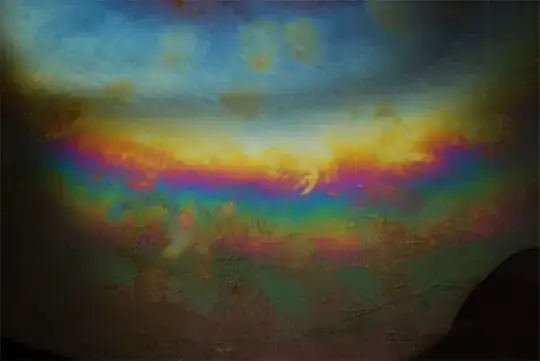

In contrast, brass acts differently when heated and tempering is somewhat different. Subjecting the piece of brass to heat you will not temper but anneal it and you get colors differently. Instead of becoming straw before blue, Brass becomes dark, starting with its pale gold to go over a dark "antique" look to before going green, teal, purple-blue, red and then losing its color like this piece of a polished brass plate shows:

Hardness/Chip

Another test that would be easy to conduct is hardness. The base idea of hardness is: An item can scratch a piece of equal or lower hardness, but not of higher hardness. If you have a chisel handy, then you have a piece of steel at hand. Most chisels are rated as HRC 58-62 - which is the Rockwell hardness scale. Brass could be all over the place, depending on work hardening. But the identification is not by the hardness but by how the chisel - or better a graver - cuts.

We expect Brass to get a smooth cut with saw tooth edges while stainless cuts smoothly and has sharp edges to the cut.

Sparktest

If you want to scrap one, get an angle grinder or another power tool to grind at the nozzle. Steel sparks red-orange to whitish and depend on the mix, Carbide sparks very short and orange. Stainless creates a HUGE shower of sparks, yellow-white and dense, no burstes and branching. Copper, aluminium and Brass do not spark. Titanium is very bright white. It can tell you what kind of steel you have.

Drilltest

As we are at destroying a pair of nozzles, why not drill them? we should have done that before subjecting it to heattreating and the grinding, but alas... Basically, we clamp the piece down and take an HSS drill to drill out the center.

Brass needs a different drill type but can be drilled and machined without coolant. Typical HSS drills from the home depot have a positive rake, brass wants neutral or negative rake to drill or machine smoothly. If the piece grabs, creates short spials and dusty small flakes with an unmodified, new drill (or under positive rake machining), it drills like brass, as you see here from a Clickspring video on drilling brass:

In contrast, stainless steel doesn't want to be machined without cooling at all and using high speed creates smoke quickly and nearly no chips at all. A moment later your tool starts to glow and gets a dull edge. If your drilling experiment turns a new drill blunt on high speeds or uncooled, you have stainless at your hands. To get chips, you need to work slow and have some sort of cooling. It is still a painfully slow process that needs a lot of pressure, but it gets larger, nesting chips like seen here from a Wayne Canning steel drilling tutorial: