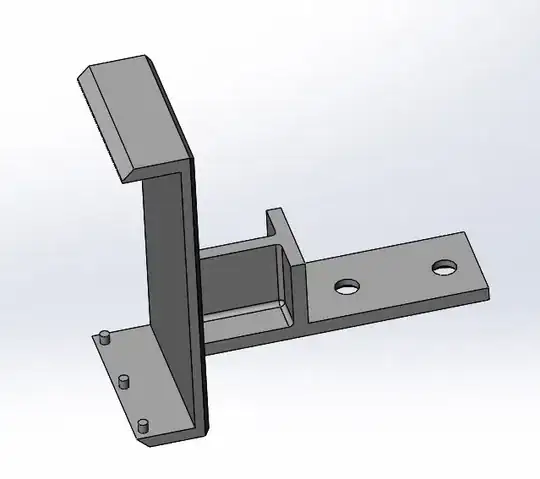

This part is quite complex and there are 3 orientations it could be printed at. I will assume picture 1 shows the item in orthonormal XYZ orientation: Z up, X to the front(-rightish) corner, Y to the (backish-)right. Using these we can chose have an XY (Pic 1), XZ (Pic 2) and YZ (Unpictured) plane of the build to touch on the build plate. Luckily this object is symmetric along the middles, so we won't need to look at two cases each.

To evaluate the best print orientation, we can look at the loads that will come to the part, the aesthetic (we get better resolutions in the Z than the XY on printers!) and of course the need for support structures and thus waste material.

Aesthetics are probably not an issue for this structural part, so let's take this part as an example and look at the three orientations and how to reason which orientation might be best.

XY

Using the lowest XY plane as build contact we will need to support the upper arc of the bracket and the back-branch with the T-support also needs support. So we need quite some support material, which is a con.

Also, the layers in the C-Clamp are aligned in such a way that the clamp might easily break in its long line, but due to the length, it might be able to bend quite some. Remember that PLA is brittle though, but you could post-process the part by baking it to generate better inter-layer bonding.

On the upside, the T-stiffening is in its most sturdy orientation and the back extension has the most stable print orientation. You might want to add extra bottom layers to fight the loss of layers that are printed on the support structure though.

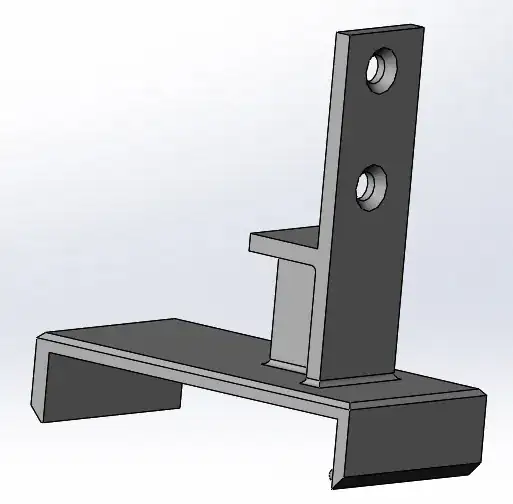

XZ

The Orientation in the 2nd Picture has moved the interlayer boundaries to be on the short arms of the C-clamp, making it more fragile than the XY orientation.

The T-stiffing and back-branch are also significantly weakened and might break on stresses into the direction we had defined as Y in the premise.

It also needs to support the whole back of the C-Clamp during print, which is a considerable amount, though probably lower than in the XY orientation.

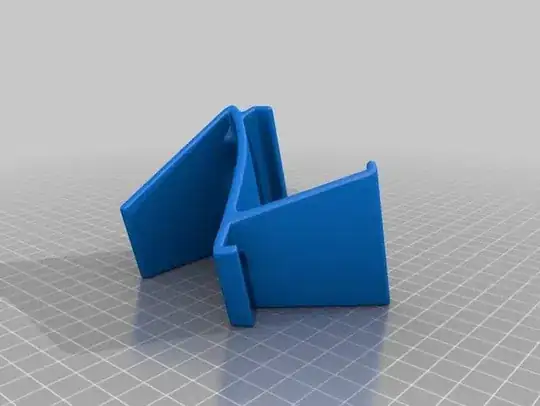

YZ

The unshown orientation puts the C-clamp in such an orientation that each layer has a complete C. This makes the clamp as sturdy as it could be.

The back-branch is quite solid along its length (Y) and the stiffening T comes as an integral part of the perimeters, making it good to take loads from the branch. It does suffer from weakening the long part against forces splitting it along the long axis, which would be directed in the X-axis of our premise.

This orientation also reduces the needed support to a minimum, as we don't necessarily need to support the "bridging" part of the T-support.

Conclusion

I would choose the YZ orientation based on both material need as well as the physical benefits of achieving the least weak configuration.

Optimisation

The print object could be slightly optimized to reduce the needed support at the cost of increasing the part weight in the YZ orientation:

As suggested, widening the T to touch the build plate and the accompanying part to do too would make the part larger and would turn the support into an integral part of the print.

One could also turn the T into a Y structure with an overline for a shorter bridge and longer stretches of the shell that can dissipate the forces on the T-bar to the clamp more effectively.