Do you have any specific process recommendations to achieve support for the parts hanging above 45 degrees, using open source software?

-

Hi VampishWolf, welcome to 3D Printing.SE! Sorry, but this question cannot be answered as SE is not about product recommendation please read [help] and take the [tour]. All slicer software applications are able to do this for you, some are free (e.g. Ultimaker Cura, Slic3r, etc.). It will be a setting in the huge pile of settings to set the support angle. Alternatively you can create the supports in the program you designed the object in or open the model in a program that can add or change the design. – 0scar Jun 03 '19 at 08:32

-

As it stands your question is a bit broad so could you clarify your question with a specific example, using a model, images, diagram? We can't really recommend software brands, but process recommendation is permitted. BTW, don't any of the other [support structure](https://3dprinting.stackexchange.com/questions/tagged/support-structures) questions answer your question? – Greenonline Jun 03 '19 at 13:34

-

I thought the slicer software like Cura or Slic3r did that for you, either automatically or with a minimum of effort. There are plenty of youtube videos to walk you thru using either too. In my famity, we (i.e. my wife) are using Cura at the moment. We've only printed 1 part that needed supports so far, it was a file we found on thingiverse and I don't know if it includede the supports or not in the file that she downloaded. – CrossRoads Jun 03 '19 at 16:30

1 Answers

PrusaSlicer has support enforcers you can place on areas that need support.

See this video: Prusa Slicer Support Enforcers.

Automatic supports

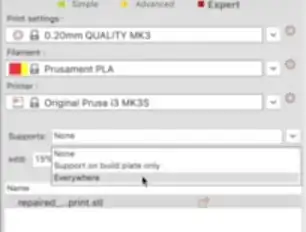

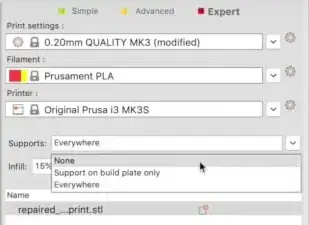

There are automatic supports, in the Supports dropdown menu, select Everywhere:

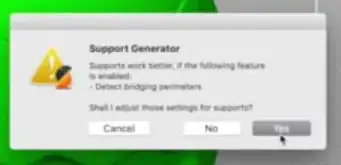

Click Yes in the resulting dialog:

Click on the Slice icon in the bottom left:

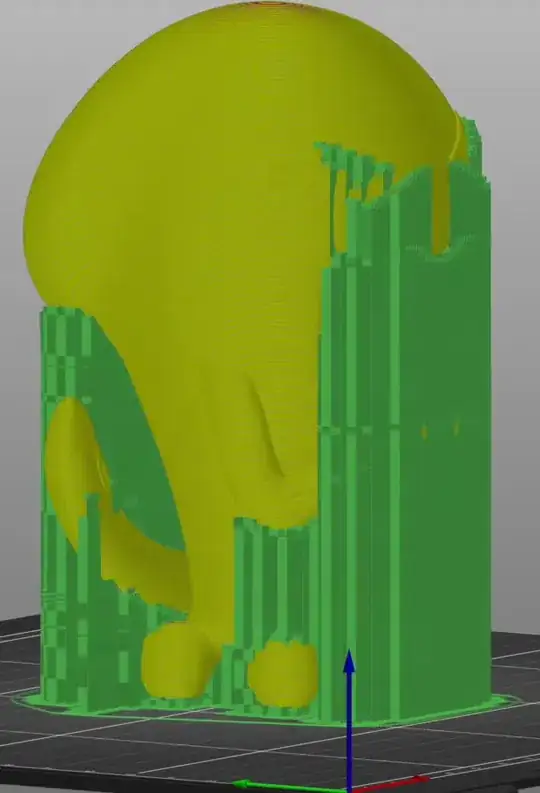

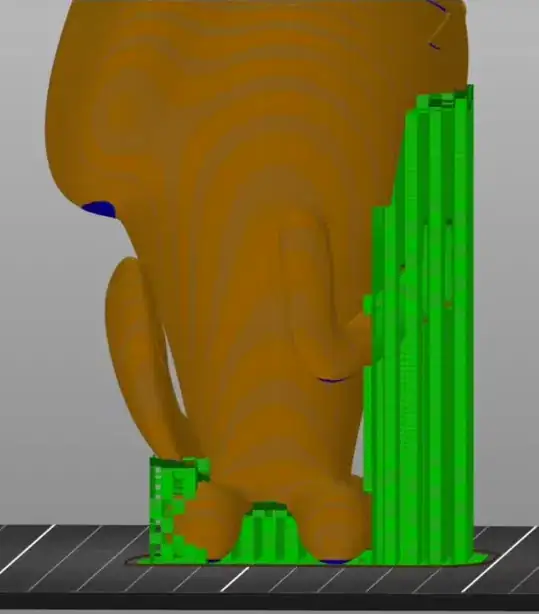

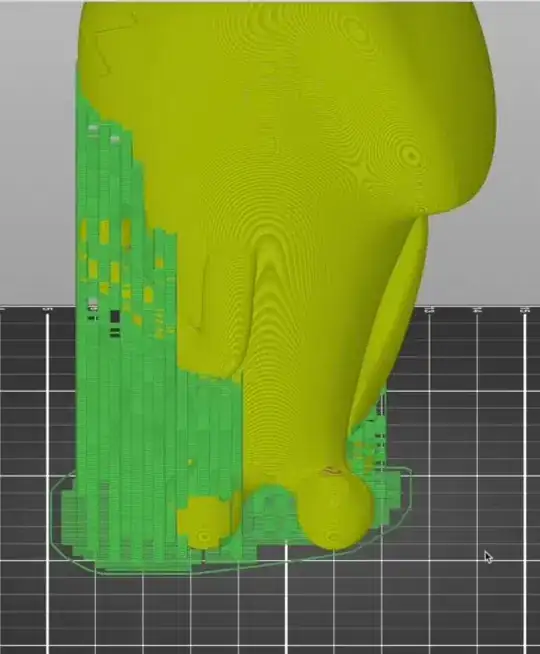

You will end up with a lot of supports:

However, this method generally results in too much support...

Custom Suport Enforcers

So turn off Supports in the drop down menu, select None:

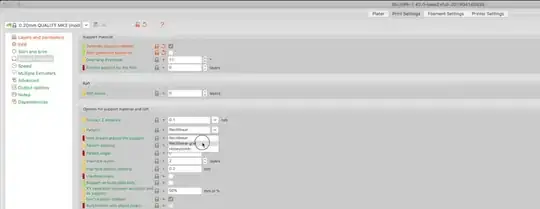

Now, in the Print Settings tab, under Support Material, disable Auto Generated Supports and enable Generate Support Material:

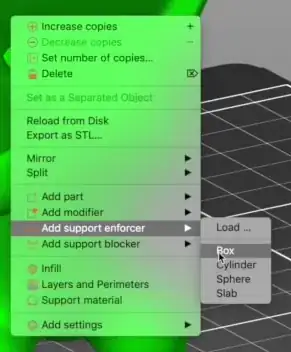

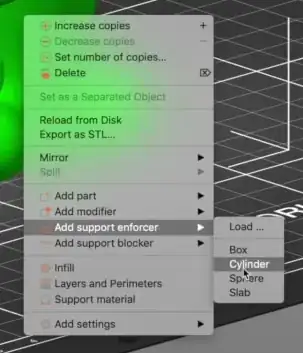

Then right click on the model and select Box from the Add Support Enforcer menu item:

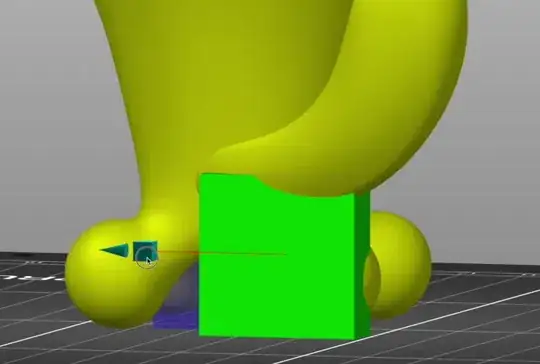

You can move by clicking the Move button in the left hand palette,

resize by clicking the Resize button

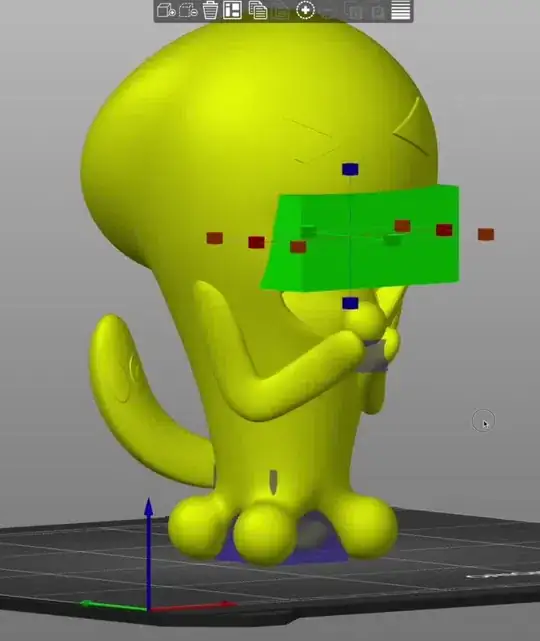

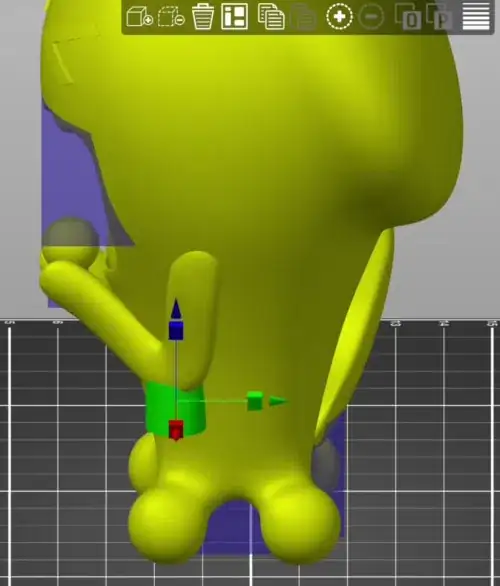

and re-shape the Box as necessary, to support the difficult overhanging parts parts only. Here we can see three boxes have been added - pale blue for the previously added boxes and green for the current box:

And a fourth final Box for the tail:

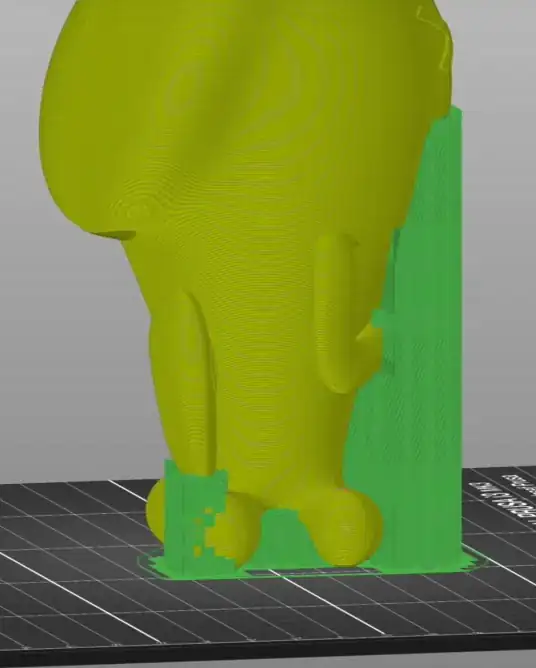

Now, when you hit the Slice button, there will be much less support structure than when using Automatic supports:

Parts of the model that the slicer thinks still needs support will be highlighted in dark blue (such as the elbow and back of the head):

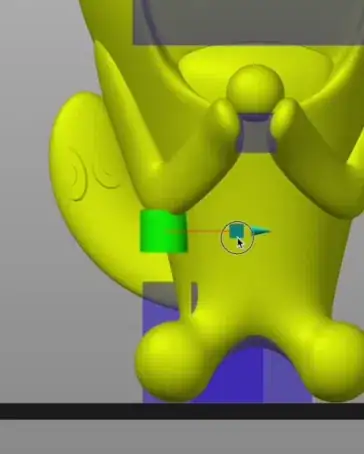

Add a cylinder support enforcer:

Resize and re-shape as before and move into position below the elbow:

Adding a second cylinder as a support enforcer

Upon hitting Slice:

Now in Print Settings - Support Material - Pattern change it from Rectilinear to Rectilinear Grid:

For prints with curves and details Rectilinear Grid works better, than Rectilinear (which is fine for supporting a plain cube in the air). It is easier to break the support off the print.

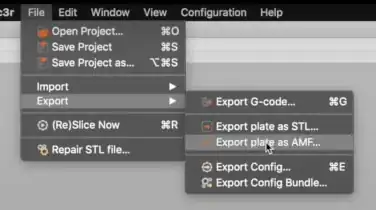

Now save your hard work as an AMF file:

This file maintains all of the support enforcers so that they can be modified if the actual print needs some adjustments - without having to re-add all of the support enforcers all over again.

-

1

-

-

1@Greenonline Perhaps it's better to make your own answer when editing that much though... – Jeroen3 Jun 04 '19 at 08:07

-

@Jeroen3, Yes, sorry about that but you found the video and I didn't want to take credit for that... :-) I must admit that when I started adding info I didn't realise that there would be so much of it! I expected only one or two screenshots. Lol. But yes, you are right, for such extensive edits, it would have been better for me to refer to your answer and add the process as my own answer. Ah well, next time I will. Thanks for finding the link anyway... it was a useful learning experience :-) – Greenonline Jun 04 '19 at 08:13